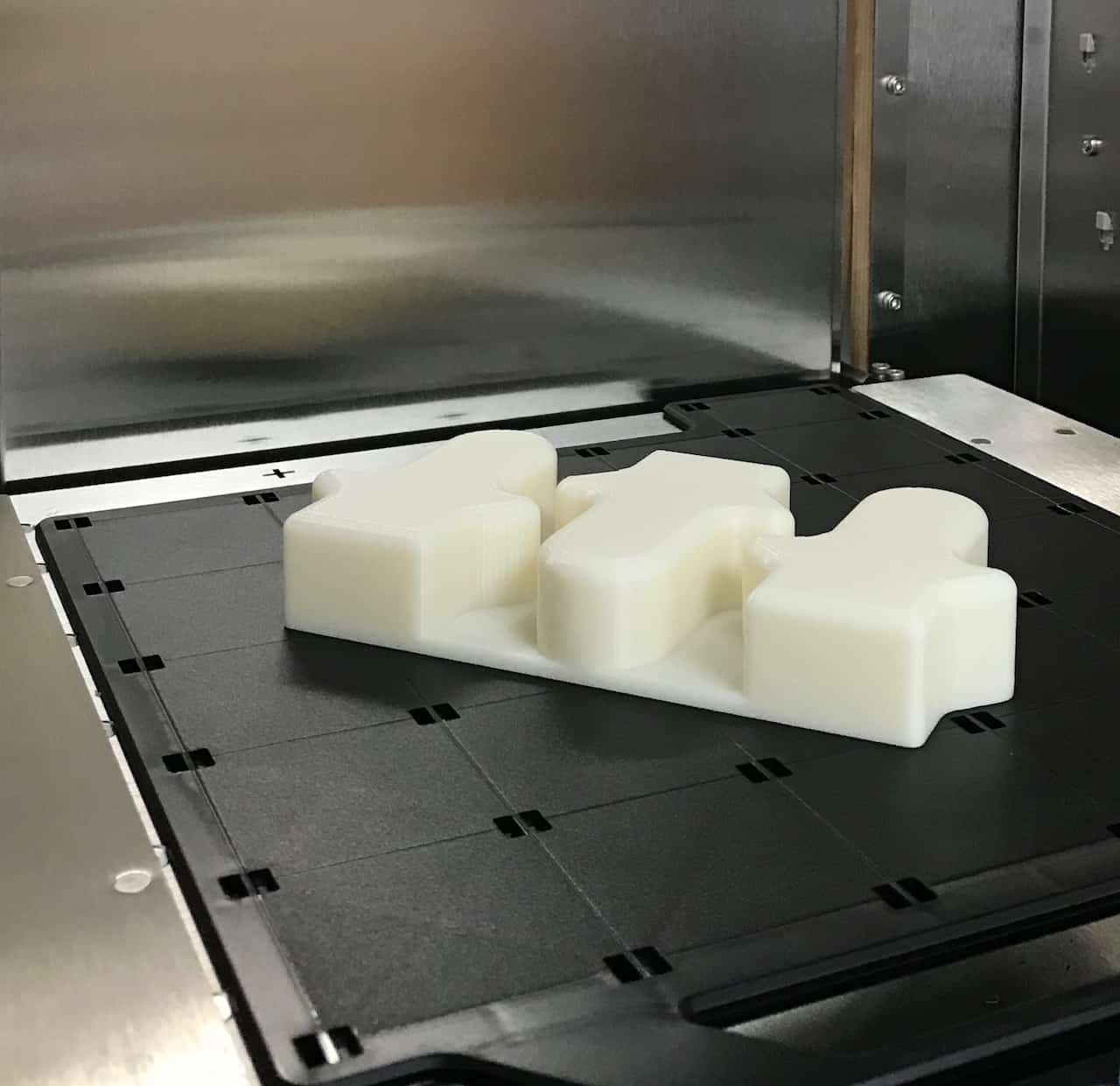

3D Printing Prototype: Rapid Prototyping

3D printing (rapid prototyping) is a process that rapidly produces a high-quality, durable 3-dimensional representation of a product or, in our case, a prototype mold to be used to create packaging samples.

Why should you consider 3D Rapid Prototype Printing?

Accelerate time-to-market by shortening design and development cycles that ultimately get products to market faster by helping fine tune package design and explore options. Typically, prototypes can be produced in 1 to 3 days. Lower production costs and reduce expensive revisions by testing fit and function at the beginning of the development process. The first 10% of the package development process can affect about 80% of the package’s total cost. Bring packaging ideas off the computer screen and into functional 3-dimensional prototypes that can be easily shared, critiqued, and improved.

How is a 3D print created?

A design is uploaded to the printing software, which translates the geometry to the 3D printer; very much like what happens between your computer and ink printer. In a matter of hours, the 3D print is ready for sampling. 10 samples of your product’s packaging can be easily formed from a 3D print mold or, a single package shell can made for fit and function purposes. The printer uses ABS (Acrylonitrile Butadiene Styrene) plastic to form the 3-dimensional part. ABS models have been used in functional and field tests like wind tunnel testing and camera mounts on a M2 Bradley tank.

ABOUT UPPI

UPPI is a worldwide developer, manufacturer and marketer of specialized, custom thermoformed plastic packaging. Our business is the design, creation, and production of effective, yet cost-efficient packaging for the retail, medical, electronics, industrial, and food industries. If you would like to learn more about our services, please do not hesitate to contact us.

- Learn About Us

- Call: (717) 766-1578

- Email: sales@uppi.com